The core technology of MVR evaporator is to recover the evaporated secondary steam and continue to use it as a heat source. Compared to traditional multi effect evaporation

Yan, it recovers and reutilizes the steam that originally needed to be cooled by circulating water.

The essence of its energy-saving lies in the fact that by inputting a small amount of mechanical energy, the thermal grade of the secondary steam that should have been discarded can be improved, and it can be reused as a heat source to release all the latent heat contained therein. The commonly used forms of steam compressors are centrifugal and Roots, both of which can achieve an effective saturation temperature rise of up to 25C in single-stage compression. But the compression temperature rise of the compressor is not necessarily better the higher it is. On the contrary, under limited heat exchange area conditions, we hope to increase the compression temperature

Try to keep the temperature rise of the compressor as low as possible, so that we can save more electricity.

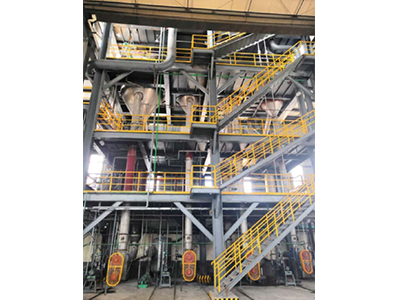

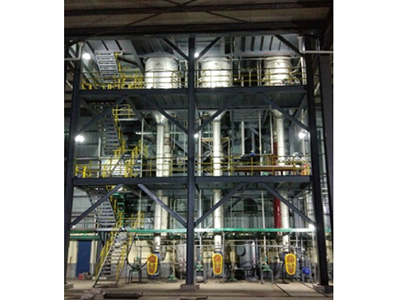

Our application examples:

Sodium chloride wastewater in the chemical industry

Sodium sulfate wastewater in the chemical industry

Chemical industry sulfide alkali

Concentrated saltwater in the coal chemical industry

Lithium battery materials industry by-product Yuanming powder

Lithium hydroxide in the lithium battery materials industry

Amino acids in the feed additive industry

tower general contractor

中文(簡體)

中文(簡體)