Product Display

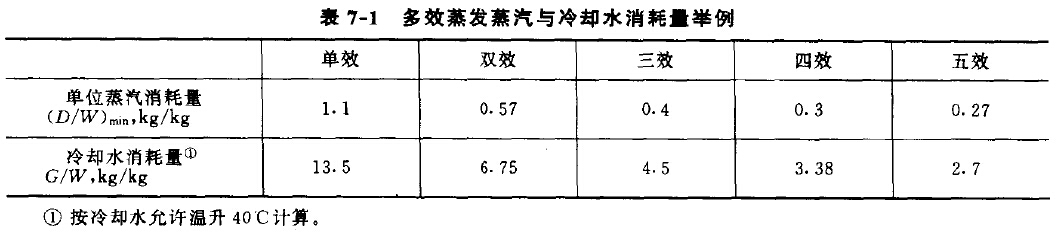

Multi effect evaporative crystallizer equipment is widely used in industries such as chemical, pharmaceutical, light industry, food, petrochemical, metallurgy, etc. It is commonly used to process large amounts of materials and vaporize a large amount of water, while achieving the goal of steam conservation. Multi effect evaporation is a system that connects multiple evaporators in series. Except for the first effect, which uses heating steam, all other effects use the secondary steam generated by the previous effect. Only the secondary steam of the last effect needs to be condensed by the cooling medium. Therefore, multi effect evaporation not only significantly saves the consumption of heating steam, but also significantly saves the amount of cooling water.

Our company has rich experience and strong technical strength. We can optimize the selection based on material characteristics and processing capacity, comprehensive investment situation, and design into dual effect, three effect, four effect, five effect, etc. In terms of process, we can design into downstream process, upstream process, mixed flow process, parallel flow process, etc. At the same time, the form can be designed as natural circulation, forced circulation, falling film evaporation, rising film evaporation, or a combination of evaporation forms. Achieve reasonable investment and meet the requirements of different products.

For crystalline materials, the crystallizer adopts a unique structural form, while integrating reasonable process and equipment design to meet the requirements of crystalline grains, while avoiding grain blockage of equipment and pipelines.

The entire system can achieve highly automated control through PLC or DCS, enabling unmanned operation throughout the entire process and suitable for continuous production. At the same time, a heating pump can be equipped for the evaporator to reduce steam consumption and provide various auxiliary equipment that is compatible with the evaporator to meet the needs of users for evaporating various materials.

working principle

Evaporation can be carried out under normal pressure, pressure or pressure reduction. Evaporation under reduced pressure is called vacuum evaporation, and the boiling point of a solution decreases below atmospheric pressure, thus increasing the effective heat transfer temperature difference.

Multi effect evaporation uses the secondary steam generated by the previous effect as the heating steam for the subsequent effect, allowing the heat to be utilized multiple times and requiring much less steam than single effect evaporation.

In industrial production, it is common to encounter the requirement to process a large amount of liquid and vaporize a large amount of water. In order to save heating steam, multi effect evaporation can be used. Multi effect evaporation is a system that connects multiple evaporators end-to-end and operates in series. The operating pressure and boiling point of the solution in the latter effect are lower than those in the former effect. Only fresh heating steam is added to the first effect with the highest operating pressure, and the generated secondary steam is passed into the heating chamber of the latter effect as the heating steam of the latter effect. That is to say, the heating chamber of the latter effect becomes the condenser of the secondary steam of the former effect. The last effect is often operated under vacuum, and only the secondary steam of the last effect is condensed with a cooling medium. Therefore, multi effect evaporation not only significantly reduces The consumption of heating steam also significantly reduces the consumption of cooling water.

tower general contractor

中文(簡(jiǎn)體)

中文(簡(jiǎn)體)