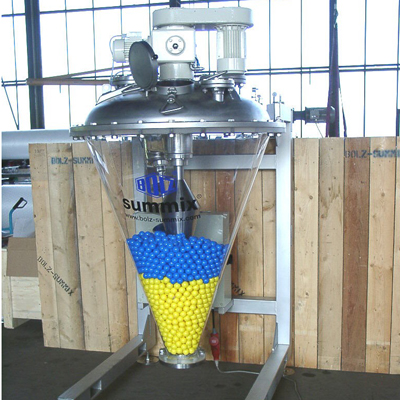

Product Display

Single cone spiral dryer is a vacuum contact dryer, especially suitable for drying dangerous goods and toxic substances with solutions or moisture. With its closed design and indirect product heating method, low moisture content products are finally processed.

Due to its unique gentle stirring characteristics, even products that are sensitive to mechanical processing will not be damaged. The dried product is not only renewable, but also of the same quality as the original product. The required driving force is relatively low. The high vacuum design of this dryer ensures low drying temperature (which is particularly advantageous for products sensitive to drying temperature), and has good thermal conductivity and fast drying time. At the same time, it also has the characteristic of low energy consumption. This conical dryer has a short drying time and a high-quality fully enclosed system. Therefore, for products with strict environmental and quality requirements, this dryer is an ideal choice.

The filter directly connected to it can retain dust particles in the processing area, and the machine unloads thoroughly and conveniently, ensuring that you can continue processing products without any loss. In addition to solids, moisture and solutions can also be recycled through the vacuum device integrated into the entire sealing system.

working principle

The jacket outside the tank is heated by a heat source, and the wet material absorbs heat and evaporates water vapor. It is extracted through a vacuum pump and a vacuum exhaust pipe. Due to the vacuum state inside the tank and the continuous flipping of the material inside and outside by the rotation of the tank, the drying speed of the material is accelerated, the drying efficiency is improved, and the goal of uniform drying is achieved.

Performance characteristics

Fully cantilevered conical stirring spiral shaft

The product is gently stirred and has good circulation

Low mechanical shear

High precision, good mixing effect, strong renewability

Suitable for producing various industrial products with a wide range of applications

Flexible load distribution (10-), no impact on product quality

There is no residue left in the discharge of material and cleaning solution from the national system

Online cleaning is efficient and simple, with thorough discharge

Fully enclosed system

Suitable for multiple materials and technologies to achieve safe and reliable sealing

Short drying time and low energy consumption

No pollution gas leakage

Adjust speed based on product characteristics

Use a heating and stirring spiral shaft to shorten the drying time

Ensure the safety of products, operators, and production environment

Can be flexibly used for processing various products

Adapt to materials

1. Products with fluidity: powders, granules, crystals, etc

2. Moist, crystalline active ingredients

3. Products sensitive to mechanical processing and high temperatures

4. Products that are easily decomposed under oxidation

5. Dangerous substances (toxic or carcinogenic substances)

6. Flammable materials and explosive powders

7. Products contaminated with flammable solutions

中文(簡體)

中文(簡體)